Open HardwareAssembly Instructions

Guides for installation and assembly of the LulzBot line of products made by FAME 3D LLC.

Guides for installation and assembly of the LulzBot line of products made by FAME 3D LLC.

Gather all the required materials:

1x- Actuator Sub-Assembly

2x- [HD-BT0235] M2x0.4 BHCS

2x- [HD-BT0041] M3x25 SHCS

6x- [HD-BT0042] M3x30 SHCS

6x- [HD-BT0043] M3x35 SHCS

4x- [HD-BT0157] M3x8 SHCS

4x- [HD-BT0128] M3x6 FHCS

2x- [HD-BT0146] M3x12 BHCS

2x- [HD-BT0162] M3x4 Set screw

1x- [HD-BT0171] M3x20 BHCS

2x- [HD-BT0197] M4 Thumb screw

8x- [HD-BT0204] M3x22 FHCS

2x- [HD-MS0430] Idler spring

4x- [HD-MS0446] Bearing

2x- [HD-NT0011] M4 Nut

2x- [HD-WA0027] Lock washer

1x- [HD-WA0038] M3 washer

1x- [PP-GP0419] Blower shroud

1x- [PP-GP0428] Idler clamp right

1x- [PP-GP0427] Idler clamp left

1x- [PP-GP0470] Cable channel E1

1x- [PP-GP0471] Cable channel E2

1x- [PP-GP0420] Actuator cover

1x- [EL-HR0145] E1 Extension harness

1x- [EL-HR0165] Standard Aero Extruder Harness

1x- [EL-HR0166] Mirrored Aero Extruder Harness

2x- [EL-HR0170] Fan guard

2x- [EL-MT0069] Half height stepper motor

1x- [PP-FP0135] Mirrored Idler lever

1x- [PP-FP0136] Mirrored filament guide

2x- [PP-FP0154] Extruder hobb

1x- [PP-FP0158] Standard filament guide

1x- [PP-FP0162] Standard idler lever

1x- [PP-MP0204] Mirrored body

2x- [PP-MP0282] Steel pinion gear

1x- [PP-MP0233] Standard body

1x- [DC-LB0175] Caution Hot tag

5x- [HD-MS0058] Cable Tie

Materials:

2x- [EL-MT0069] - NEMA 17 Half Height Stepper Motor

2x- [PP-MP0282] - E3D Aero Steel Pinion Gear

2x- [HD-BT0162] - Alloy Steel Cup Point Set Screw M3x4

Using the GEAR HEIGHT spacing jig , line up the set screw with the flat side of the motor shaft.

Apply Blue Loctite and torque the set screw to 3 in*lbs

Repeat for the second motor.

Materials:

Actuator Sub-Assembly

1x- Motor with pinion gear attached

1x- [PP-MP0233] - Standard body

1x- [HD-WA0027] - Lock washer

1x- [HD-BT0146] - M3x12 BHCS

1x- [HD-MS0446] - Radial Ball Bearing

1x- [PP-FP0154] - Extruder hobb

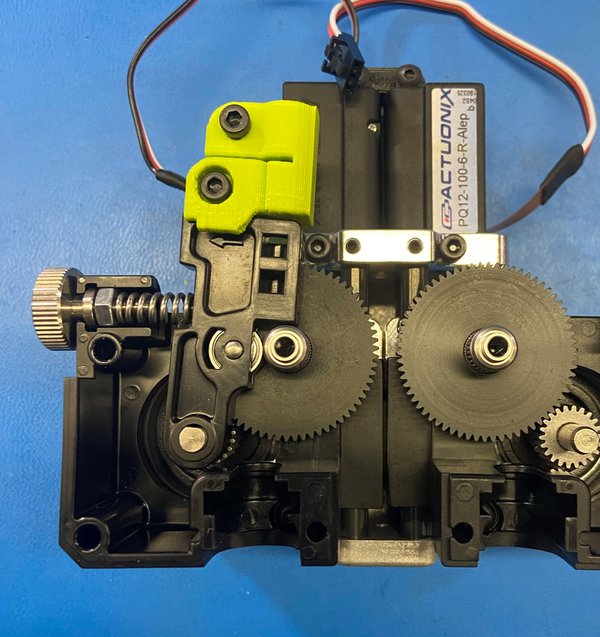

Start by installing the Radial Ball Bearing [HD-MS0446] into the Standard body [PP-MP0233]

Next place motor with pinion gear under the motor plate on the actuator sub-assembly

Make sure the motor connector is facing the left as shown

Slide the jig over the bottom plate on the actuator sub-assembly and make sure the actuators are extended so the motor plates are tight against the jig.

Then place the standard body with bearing over the motor plate and insert the extruded hobb [PP-FP0154] through the bearing on the standard body.

Using 1x M3x12 BHCS [HD-BT0146] and 1x M3 Lock washer [HD-WA0027] while holding the motor up, so that the gears mesh together, secure the motor and standard body to the actuator sub-assembly.

Torque to 5in lbs

Materials:

Actuator Sub-Assembly (with jig still attached for step 3)

1x- Motor with pinion gear attached

1x- [PP-MP0204]- Mirrored body

1x- [HD-WA0027] - Lock washer

1x- [HD-BT0146] - M3x12 BHCS

1x- [HD-MS0446] - Radial Ball Bearing

1x- [PP-FP0154] - Extruder hobb

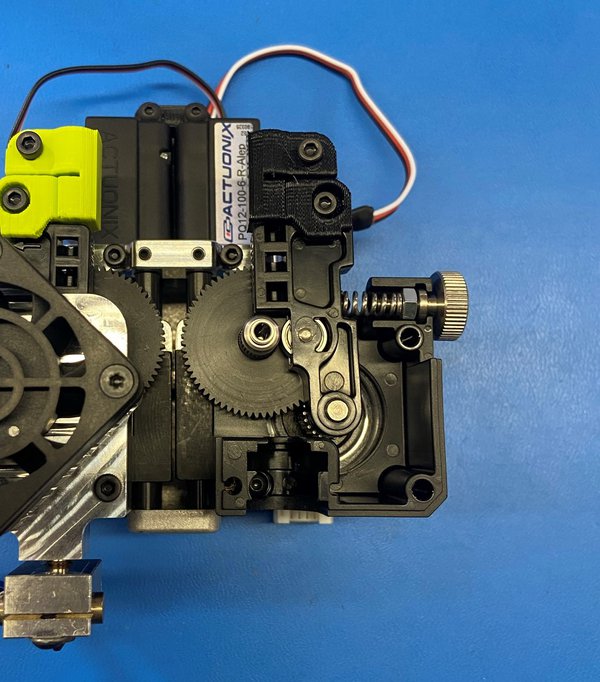

Start by installing the Radial Ball Bearing [HD-MS0446] into the Mirrored body [PP-MP0204]

Next place motor with pinion gear under the motor plate on the actuator sub-assembly

Make sure the motor connector is facing the bottom of the actuator sub-assembly as shown

Then place the mirrored body with bearing over the motor plate and insert the extruded hobb [PP-FP0154] through the bearing on the mirrored body.

Using 1x M3x12 BHCS [HD-BT0146] and 1x M3 Lock washer [HD-WA0027] while holding the motor up, so that the gears mesh together, secure the motor and mirrored body to the actuator sub-assembly.

Torque to 5in lbs

Materials:

Assembly from step 4

1x- [HD-BT0041] - M3x25 SHCS

2x- [HD-BT0043] - M3x35 SHCS

2x- [HD-BT0157] - M3x8 SHCS

1x- [HD-BT0197] - M4 Thumbscrew

4x- [HD-BT0204] - M3x22 FHCS

1x- [HD-MS0430] - Idler Spring

1x- [HD-MS0446] -Radial Ball Bearing

1x- [HD-NT0011] - M4 Nut

1x- [PP-GP0427] - Standard Idler Clamp

1x- [EL-HR0165] - Standard Aero Extruder Harness

1x- [EL-HR0170] - Fan Guard

1x- [PP-FP0158] - Standard Filament Guide

1x- [PP-FP0162] - Standard Idler Lever

Using 2x M3x8 SHCS [HD-BT0157] attach the Standard Idler Clamp [PP-GP0427] to the Standard Idler Lever [PP-FP0162]

Make sure the hole for the filament is aligned between the idler clamp and the idler lever

Assemble the thumbscrew tension spring by screwing the M4 nut [HD-NT0011] to the base of the M4 Thumbscrew [HD-BT0197], finish by placing the Idler Spring [HD-MS0430] over the end of the threads.

Apply Super Lube to the thumb screw and thread the nut on and off the thumbscrew a couple of times

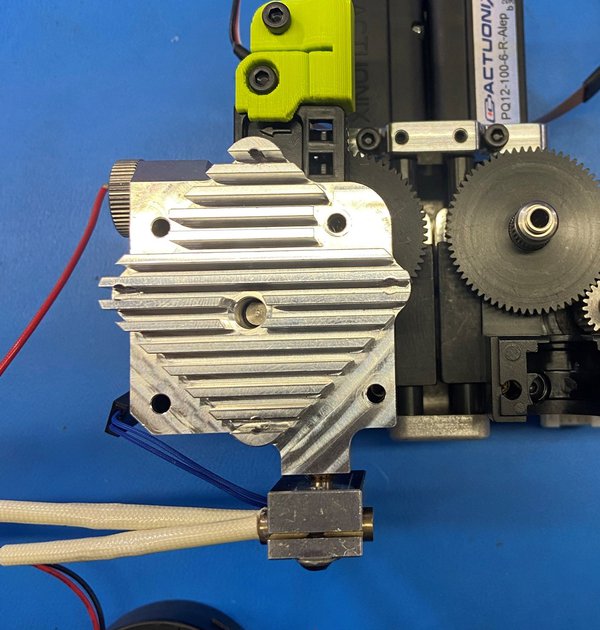

Place 1x Radial Ball Bearing [HD-MS0446] in the bearing cavity on the Standard Aero Extruder Harness [EL-HR0165]

Place the idler lever assembly over the motor shaft, ensure the idler bearing is facing towards the extruded hobb.

Place thumbscrew assembly into the cavity of the standard body, the end of the spring should fit over the nub on the idler lever.

Put the Standard Filament Guide [PP-FP0158] into the cavity below the hobb.

Filament guides should only fit in corresponding extruded body, make sure the bottom of the filament Guide shows 2.85R and not 2.85L

Place the Standard Aero Extruder Harness [EL-HR0165] onto the assembly, make sure the hobb shaft and filament guide are not out of alignment.

Install 1x M3x35 SHCS [HD-BT0043] into the top right hole of the front plate, and Install 1x M3x25 SHCS [HD-BT0041] into the lower right hole. Then using 1x M3x35 SHCS [HD-BT0043] place the ground wire around the screw and fasten the screw into the top left hole making sure the ground wire point outwards.

Torque these to 3in lbs

Finish by placing the fan, fan guard [EL-HR0170] over the Standard Aero Extruder Harness, and secure using 4x M3x22 FHCS [HD-BT0204].

Be sure the fan is in the correct orientation. The label should not be visible.

Materials:

Assembly from step 5

1x- [HD-BT0041] - M3x25 SHCS

2x- [HD-BT0043] - M3x35 SHCS

2x- [HD-BT0157] - M3x8 SHCS

1x- [HD-BT0197] - M4 Thumbscrew

4x- [HD-BT0204] - M3x22 FHCS

1x- [HD-MS0430] - Idler Spring

1x- [HD-MS0446] -Radial Ball Bearing

1x- [HD-NT0011] - M4 Nut

1x- [PP-GP0428] - Mirrored Idler Clamp

1x- [EL-HR0166] - Mirrored Aero Extruder Harness

1x- [EL-HR0170] - Fan Guard

1x- [PP-FP0135] - Mirrored Idler Lever

1x- [PP-FP0136] - Mirrored Filament Guide

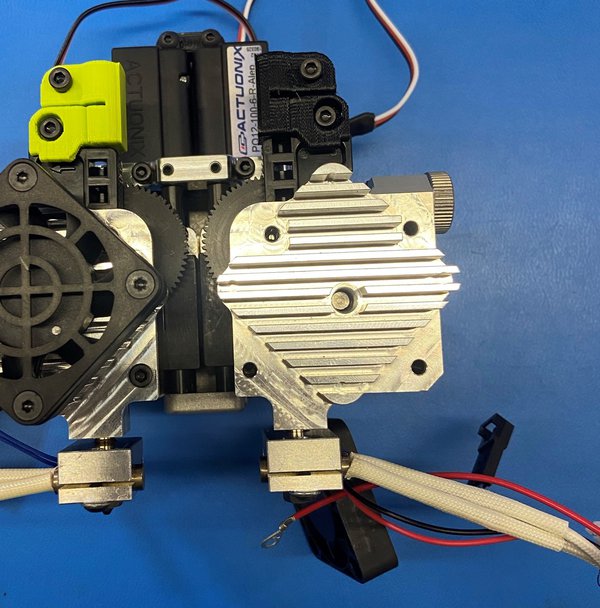

Using 2x M3x8 SHCS [HD-BT0157] attach the Mirrored Idler Clamp [PP-GP0428] to the Mirrored Idler Lever [PP-FP0135]

Make sure the hole for the filament is aligned between the idler clamp and the idler lever

Assemble the thumbscrew tension spring by screwing the M4 nut [HD-NT0011] to the base of the M4 Thumbscrew [HD-BT0197], finish by placing the Idler Spring [HD-MS0430] over the end of the threads.

Apply Super Lube to the thumb screw and thread the nut on and off the thumbscrew a couple of times

Place 1x Radial Ball Bearing [HD-MS0446] in the bearing cavity on the Mirrored Aero Extruder Harness [EL-HR0166]

Place the idler lever assembly over the motor shaft, ensure the idler bearing is facing towards the extruded hobb.

Place thumbscrew assembly into the cavity of the mirrored body, the end of the spring should fit over the nub on the idler lever.

Put the Mirrored Filament Guide [PP-FP0136] into the cavity below the hobb.

Filament guides should only fit in corresponding extruded body, make sure the bottom of the filament Guide shows 2.85L and not 2.85R

Place the Mirrored Aero Extruder Harness [EL-HR0166] onto the assembly, make sure the hobb shaft and filament guide are not out of alignment.

Install 1x M3x35 SHCS [HD-BT0043] into the top left hole of the front plate, and Install 1x M3x25 SHCS [HD-BT0041] into the lower left hole. Then using 1x M3x35 SHCS [HD-BT0043] place the ground wire around the screw and fasten the screw into the top right hole making sure the ground wire point outwards.

Torque these to 3in lbs

Finish by placing the fan, fan guard [EL-HR0170] over the Mirrored Aero Extruder Harness, and secure using 4x M3x22 FHCS [HD-BT0204].

Be sure the fan is in the correct orientation. The label should not be visible.

Materials:

Assembly from step 6

2x- [HD-BT0042] - M3x30 SHCS

2x- [HD-BT0043] - M3x35 SHCS

1x- [PP-GP0470] - Left Cable Channel

1x- [PP-GP0471] - Right Cable Channel

Using a Phillips head screwdriver, remove the outer bottom screw from both motors. (Place Moons Motor bolt in designated bin)

Start with the Standard Aero Extruder Harness (Left side)

First make sure the wire sheathing is 50 mm long if it's long then trim down to 50mm

Connect the two wires for the thermistor and slide it in the Left Cable Channel [PP-GP0470]

Then take the two white hot end wires and place them in the left cable channel next to the thermistor connector

Take the rest of the wires except for the motor wire and place them in the cable channel

Make sure the blower fan wire follows the side of the cable channel [reference#1]

Then keeping all the wires in the cable channel, secure both end using 1x M3x30 SHCS [HD-BT0042] and 1x M3x35 SHCS [HD-BT0043], use the M3x30 SHCS on the motor side and the M3x35 SHCS one the side with the fan. Do not Over-Tighten or cable channel may break

Check work, making sure the wires are fully inside the cable channel and that the cable channel is parallel with the toolhead

Wrap the motor wire around all of the other wires two time then plug it into the motor

Start on the Mirrored Aero Extruder Hardness

Connect the two wires for the thermistor and slide it in the Right Cable Channel [PP-GP0471]

Then take the two white hot end wires and place them in the right cable channel next to the thermistor connector

Take the rest of the wires place them in the cable channel

Make sure the motor wire follows the side of the cable channel [reference#2]

Then keeping all the wires in the cable channel, secure both end using 1x M3x30 SHCS [HD-BT0042] and 1x M3x35 SHCS [HD-BT0043], use the M3x30 SHCS on the rear motor side and the M3x35 SHCS on the front side with the fan. Do not Over-Tighten or cable channel may break

Check work, making sure the wires are fully inside the cable channel and that the cable channel is parallel with the toolhead

Materials:

Assembly from step 7

1x- [PP-GP0420] - Actuator Cover

2x- [HD-BT0128] - M3x6 FHCS

7x- [HD-MS0058] - Zip Tie

1x- [EL-HR0145] - E1 Extension harness

Feed the two actuator wires through the Actuator Cover [PP-GP0420] then slide the actuator cover over the actuators, make sure not to pinch the fragile ribbon cable. Fasten the actuator cover to the assembly using 2x M3x6 FHCS [HD-BT0128]

Using 4x Zip Ties [HD-MS0058] secure the sheathing around the two Aero Extruder harnesses. Use two zip ties for both wires one and the top of the sheathing and one at the bottom.

Route the mirrored harness under the actuator cover, so it's in between the actuator cover and the motor, then route it through the channel on the actuator cover and secure with a zip tie with the head facing outwards.

Using 2x zip ties, secure the two actuator wires to the actuator cover making sure the zip tie heads are facing outwards.

Extend the actuator on the left side as shown in [reference#3]

Take the end of the standard aero extruder harness and slide it through the actuator cover making sure the two tabs on the side snap into place, then take the E1 Extension Harness [EL-HR0145] and connect it to the standard aero extruder harness.

Make sure the white wires on the extension harness are facing the front of the toolhead.

Materials: Assembly for step 8

1x- [PP-GP0419] Blower Shroud

1x- [DC-LB0175] Caution Hot Tag

2x- [HD-BT0235] M2x0.4 BHCS

2x- [HD-BT0128] M3x6 FHCS

1x- [HD-BT0171] M3x20 BHCS

1x- [HD-WA0038] M3 Washer

Using 2x M2x0.4 BHCS [HD-BT0235], 1x Caution Hot Tag [DC-LB0175], and 1x Blower Shroud [PP-GP0419] attach the caution hot tag to the blower shroud making sure the bottom of the tag is on the same side that has the flat edge.

Attach the blower shroud with the hot tag to the assembly from step 8 using 2x M3x6 FHCS [HD-BT0128]

Using 1x M3x20 BHCS [HD-BT0171] with 1x M3 Washer [HD-WA0038] attach the fan to the blower shroud

Remove the Hex Key from the text bar and align the two prongs on the test bar with the two holes on the back plate of the actuators.

Then place the Hex Key in either the left or right hole to secure the tool head to the test bar

Note: You have to wiggle the Hex Key around before you can slide it all the way down

Power on the test stand

Are both heat sink fans running? If not the unit has failed.

Navigate to the TAZ Pro Test.gcode in the USB Drive menu and select "Print"

Grab the probe and touch it to the left nozzle

Wait for the tool head to switch to the right nozzle then Touch the probe to the right nozzle

While switching extruders, watch the blower shroud and both movements to ensure no interference or binding occurs.

You must observe the following:

Both hot ends will heat to 250C and then the test stand will cycle both extruder motors in both directions.

Make sure the hot ends heat evenly with no long pauses or jumps and that the extruders are moving in the correct directions

The test stand will now cycle the cooling fan, first at 6%, then at 50%, and lastly at 100%. Verify the fan spins at all three speeds.

The hot ends will then cool to 35C for handling before completing the test gcode, utilizing the cooling fan to slightly accelerate the cooling time.

MINTEMP, MAXTEMP, and HEATING FAILED are possible failure modes.

1x- [AS-TH0074] TAZ Pro Dual Extruder Tool Head

2x- [HD-TB0007] TAZ Pro, Feed Tube

1x- [DC-MS0054] Firmware Update Warning Cards

1x- [DC-MS0060] CONGRATULATIONS!- Accessory Instruction Card

1x- [DC-LB0213] TAZ Pro, Front and Back Label

1x- [SH-PA0066] TAZ Pro, Tool Head Box 8" x 8" x 6"

1x- [SH-PA0065] TAZ Pro, Tool Head Korrvu Insert

1x- [SH-PG0131] #260 White Reinforced Gummed Tape with LulzBot Printed Logo

Take the flattened TAZ Pro, Tool Head Box 8" x 8" x 6" [SH-PA0066] and unfold it so it stands up, then take the two bottom tabs that are next to the tab with the red stamp and fold them in,

Next fold in the tab with the red stamp and the tab across from it.

Take a piece of packing tape and tape the bottom of the box

Fold the two sides without the finger holes up so that there is space for the tool head under the plastic wrap

Place the TAZ Pro Dual Extruder Tool Head [AS-TH0074] under the plastic wrap on the Korrvu [SH-PA0065]

Fold the left side of the Korrvu back then fold the right side back then fold the top and bottom side up so it holds the left and right sides folded back so the plastic wrap is stretched around the tool head

Then place the Korrvu and tool head inside the box

Place 2x Feed Tubes [HD-TB0007] inside the box onto of the tool head.

Note: wrap the two feed tubes into a circle

Next place the CONGRATULATIONS! Accessory Instruction Card [DC-MS0060] on top of the tool head and place the Firmware Update Warning Card [DC-MS0054] over the congratulations card

Now close the box and take it to the Uline tape machines.

Use #260 White Reinforced Gummed Tape with LulzBot Printed Logo [SH-PG0131]

Select the short length on the machine.

Place the tape on one of the tabs about half way on, then fold the tab in so the tape secures both tabs together then make sure the tape runs down both sides of the box to secure the box from opening